Tìm kiếm

Danh mục sản phẩm

Hỗ trợ trực tuyến

Ms Hồng Vân

Tel: 024 3776 2357

Mobile: 0913 627 258

Email: vuvan68@gmail.com

Warning: Illegal string offset 'tabs' in /home/tinknockervn/domains/tinknockervn.com/public_html/var/compiled/customer/%%22^223^2234FED1%%default_template.tpl.php on line 89

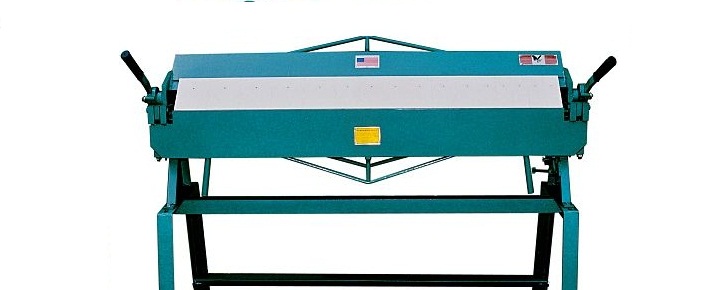

TK 2450 Manual Slip Roll

TK 2450 Manual Slip Roll

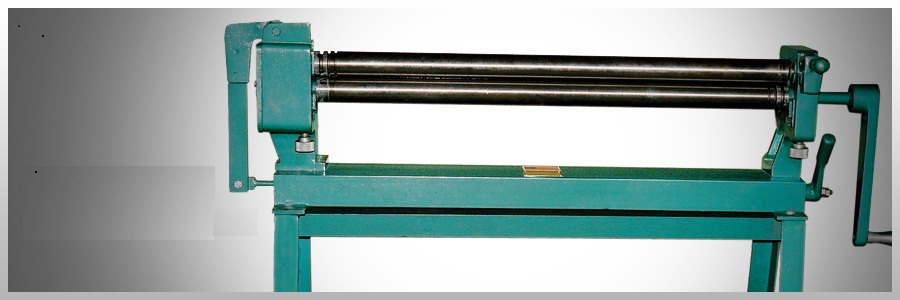

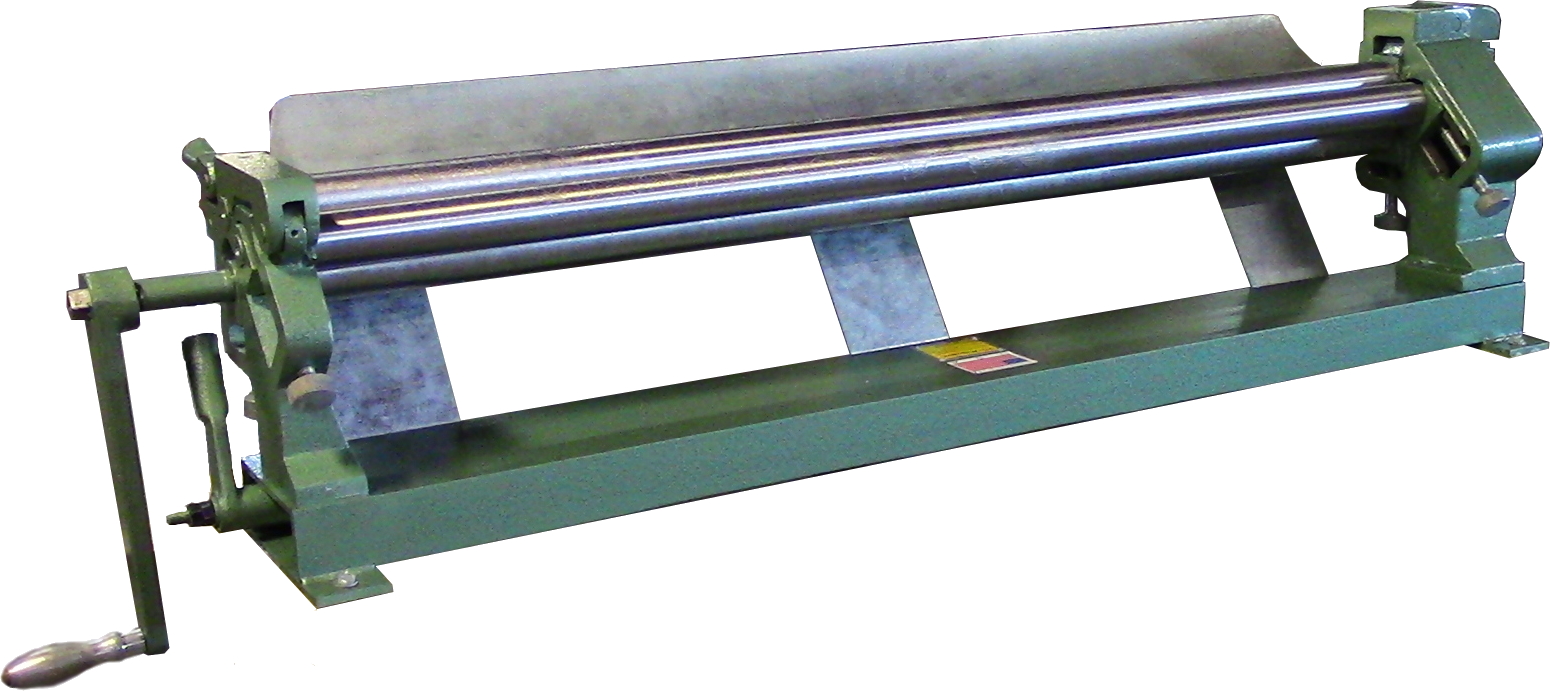

Forming Machines, or Slip Roll Formers, are intended for rolling sheet metal or forming cylinders of various diameters.

The two pinch rolls feed the sheet against the rear roll, curving the sheet and forming the cylinder. The rear or forming roll can be adjusted by screws on the rear of left and right end housings, varying the diameter of the required cylinder. Pinch rolls can be adjusted for stock thickness by screws on front of end housings.

The capacity ratings of Tin Knocker forming machines are based on forming mild steel, fully annealed, the full length of the rolls and are considered as standard by the sheet metal trade for forming rolls of a specified diameter and length. Definite capacities, however, depend upon the diameter and length of cylinder to be formed and the number of passes through the rolls to obtain a given diameter. Stiffness of material and uniformity desired are also factors. When a forming machine is overloaded, the immediate result will be deflection in the center of the rolls, resulting in cylinders bulged in the center.

To reduce the number of rear roll adjustments when sheets are of light gauge, proceed as follows:

1) Insert the sheet between two pinch rolls.

2) Bend the sheet upwards and slightly around the top roll.

3) Continue to pass the sheet through the machine.

This will also reduce the flat spot on the leading edge of the sheet.

The right-hand housing is provided with a hinged journal cap and lifting latch. After the cylinder is formed, the latch is lifted and the lever is pressed down. This raises the top roll and the cylinder can be slipped off the roll without distortion.

Forming machines are provided with grooves in the right end of the lower and rear rolls to allow for forming cylinders with a wired edge.

WARNING: Before operating, machines must be bolted to work bench. If floor stand

has been provided, machine must be bolted to floor stand with bolts provided. Stand must be securely lagged to floor.

Tin liên quan

- TK Jacketing Shear (05/04/2018)

- TK POWER CRIMPER BEADER (05/04/2018)

- Máy bẻ mí có động cơ TK30 (Máy làm ống gió – TK No.30 Pow... (05/04/2018)

- Máy gấp tole mặt bích (TDF)- TK616 (TK 616 Universal Brake) (05/04/2018)

- Tin Knocker NO.2 Hand Shears (05/04/2018)